Topflight’s innovative product development department can help you consider manufacturability in your designs as well as provide input on required validation and testing methods. Our engineering services begin in our rapid prototype lab, where our highly skilled engineering staff can utilize an existing Illustrator AI, Corel Draw, DWG AutoCAD or DXF file to produce a prototype, or can assist in creating a drawing according to your specifications. Collaborative engineer-to-engineer communication allows for an innovative design support partnership approach.

All materials, adhesives, and equipment are evaluated and qualified to provide the most efficient and effective design solution. Master Design Files are developed and approved between Topflight and our customer’s project team to ensure successful progression through each stage gate of the development process.

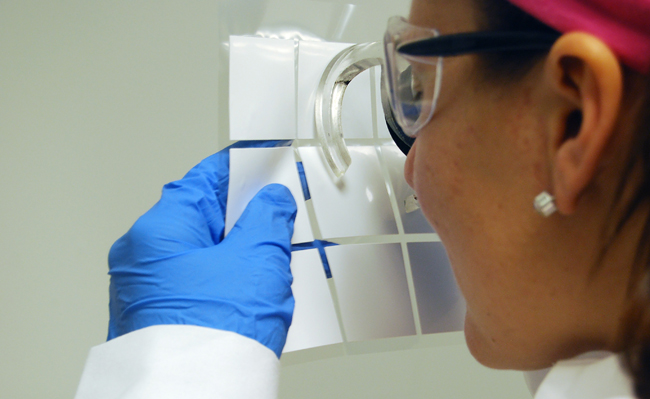

Rapid Prototyping

Topflight’s rapid prototype lab gives your designers and engineers the opportunity to test performance on pre-commercial quantities of parts before committing to expensive production tooling and setup costs. Prototyping offers the flexibility of evaluating and changing a design with the assurance of future scalability to production quantities.

Customers can request sample materials on hundreds of adhesives and substrates such as papers, films, foams, conductive tapes, filter media, membranes, wovens, non-wovens, hydrogels, hydrocolloids, skin contact, plastics, and foils. Die-cut components and multi-layer laminations in multiple configurations can be ordered to test your design alternatives. Many samples can be turned around in 48 hours or less on in-stock materials. Most samples can be produced on equipment that does not require tooling, like the CO2 laser or flatbed cutter/plotter. All prototype equipment is matched to full-scale production equipment, ensuring ramp-up manufacturability.

Product Development

Topflight’s R&D engineers work with projects in the product development stage to create parts that meet performance and manufacturability requirements. Using CAD and other design software packages, the team can produce working prototypes from hundreds of in-stock materials in as little as 48 hours. Our prototype lab is fully equipped with laser cutting, digital flying knife cutting, a flatbed punch press and a lamination and assembly station. We support both OEM’s and start-up companies in the manufacture and commercialization of products for diagnostic tests and strips, microfluidics, advanced wound care, biosensors, patient monitoring, consumer patches and tapes, disposable surgical devices, and many other medical products, as well as products in a variety of other markets and industries.

Material Expertise

Topflight works together with our customers to take products through the entire development lifecycle, from design concept, to regulatory approvals, market launch and full scale production. At the earliest stages of product development, Topflight recommends and sources raw materials from dozens of vendors. We have long standing relationships with top PSA, medical fabric, foam, gel and coatings suppliers such as 3M, Adhesives Research, Fasson/Avery Dennison, FLEXcon, MACtac, and DuPont.